SWEDEN

SWEDEN Self-ordering Platform

A digital ordering solution for the food & beverage industry

GERMANY

GERMANY According to WHO reports, deficiencies in food hygiene cause 600 million diseases each year and impede socioeconomic development by straining health care systems and harming national economies and trade.

HACCP (Hazard Analysis and Critical Control Points) principles guarantee the safety of consumers by ensuring that the food processes meet legal and regulatory requirements. HACCP is mandatory for every company that produces, markets, processes, or transports food.

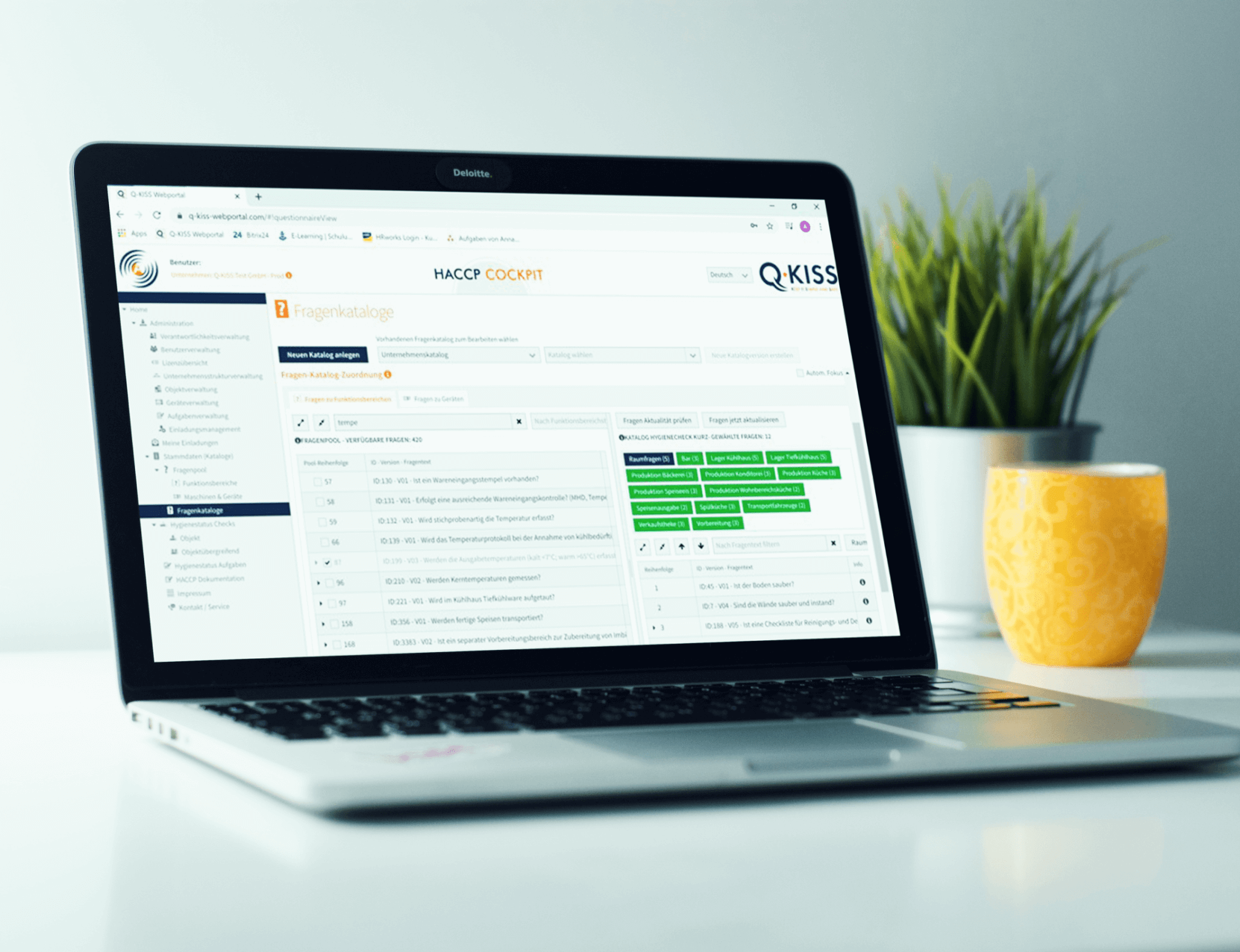

Q-KISS HACCP was developed by the food hygiene specialists of DR.SCHNELL from their daily practice with customers and associations for practical use. The project aimed to set up a self-checking system in just a few clicks, even if you are not a specialist.

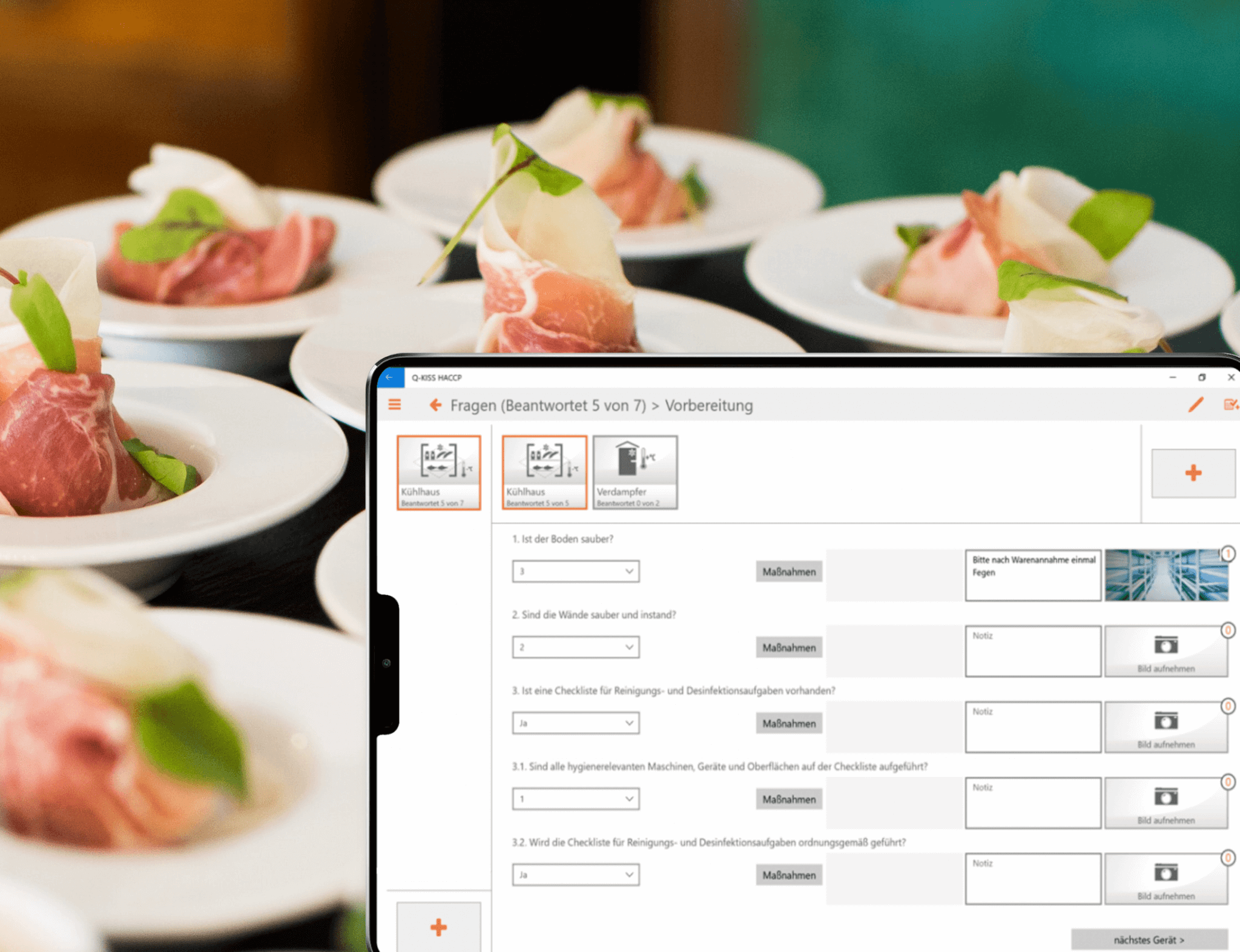

The most important food safety violations are quickly identified and production processes made safe: improper holding or refrigeration temperatures, insufficient hand washing, improper cooking, etc.

Q-KISS allows HoReCa and food businesses to automate inspection and control of the hygiene process according to HACCP standards, improving the levels of food safety and sanitation. The system can be set for different properties regardless of whether it is a hospital, hotel or caterer.

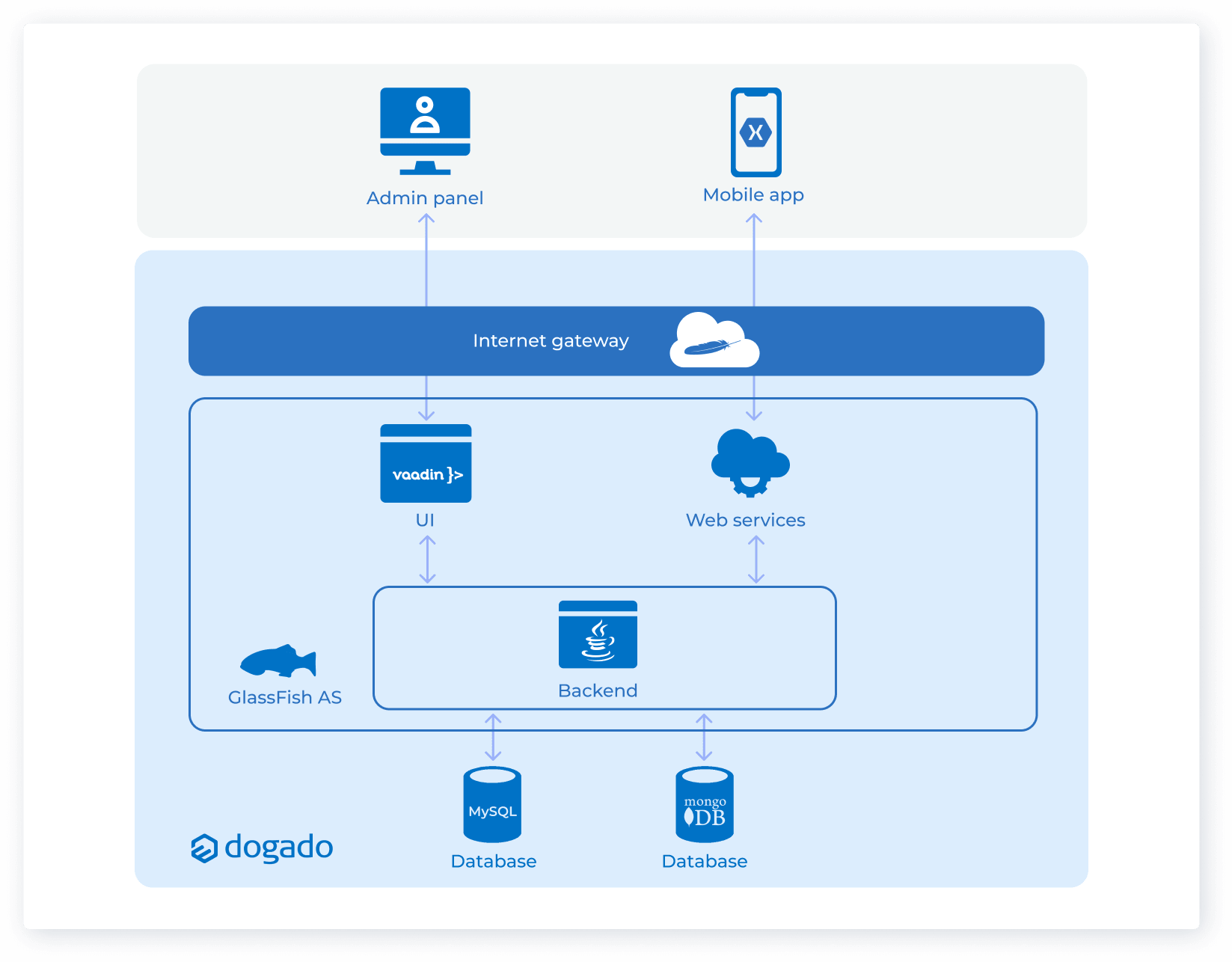

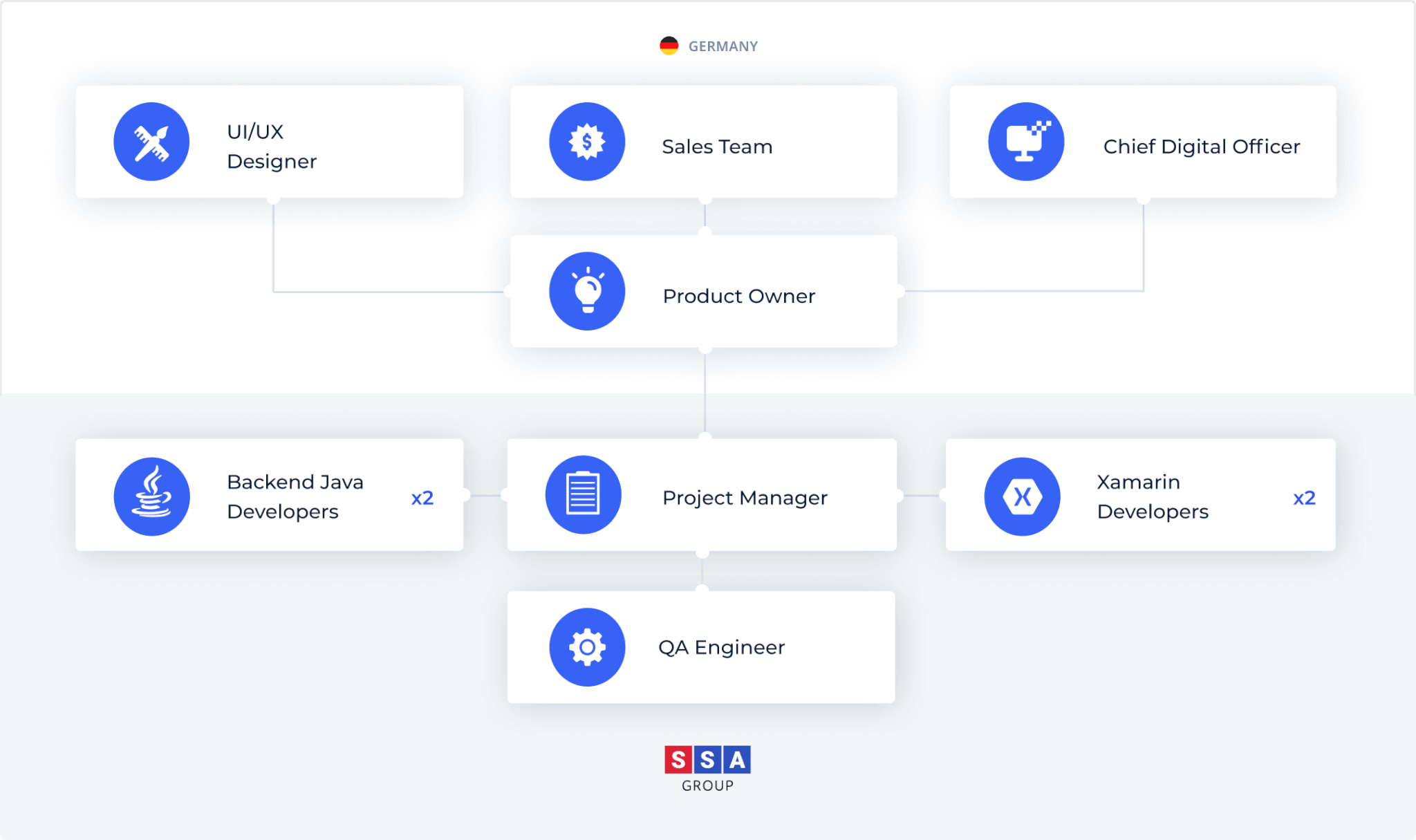

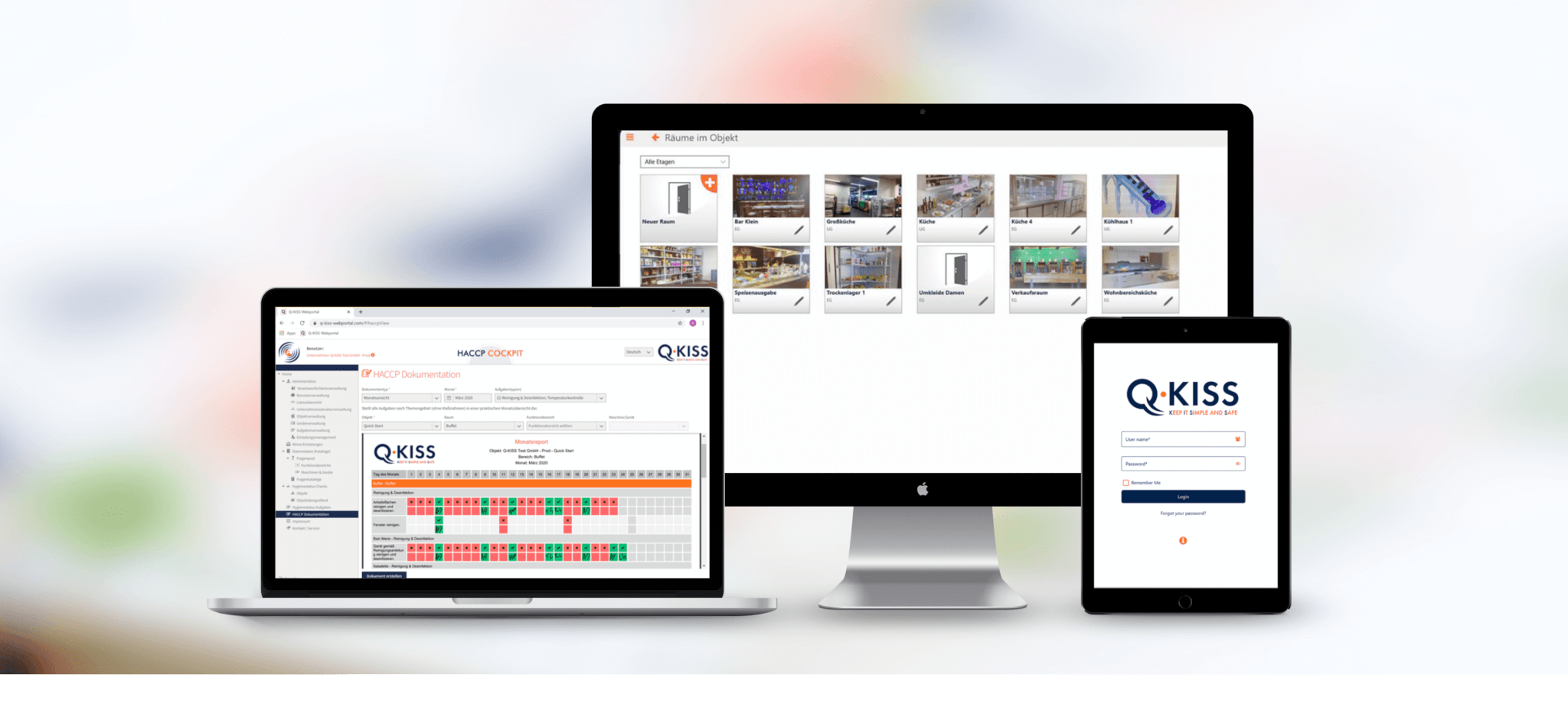

The solution combines the administrative panel and mobile and tablet apps to control hygiene-relevant parameters and facilitate hygiene checks. The system replaces paper checklists and creates online reports as well as HACCP documentation. Q-KISS Quick Check enables the business to carry out self-monitoring tours using a detailed questionnaire.

SSA Group helped implement the platform that automates hygiene process management. The solution:

SWEDEN

SWEDEN A digital ordering solution for the food & beverage industry

NORWAY

NORWAY Property management system for HoReCa businesses

Keep a close watch on your inbox. We’ll get in touch with you in no time.

Please fill out the quick form and we’ll be in touch with lightning speed

you're currently offline